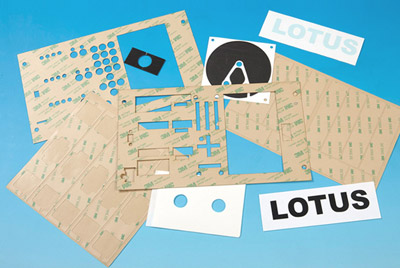

Special Purpose Adhesives, Adhesive Tapes and Die Cut

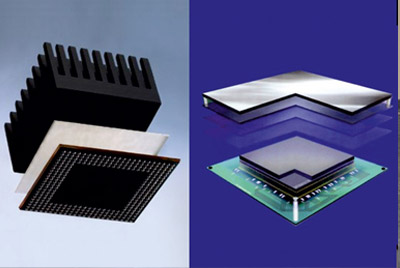

Tapes with electrical conductivity, heat dissipation properties are supplied in customized shape. Most users include LED assemblers, keyboard manufcturers.

Lotus Tapes offers a robust line of Electrically Conductive Tapes & Films designed specifically for use in EMI shielding and grounding applications. Not only do they minimize EMI noise and crosstalk, but they also provide EMI protection from a wide range of frequencies, adhere well to a variety of substrates, and can be die-cut to the custom size and shape needed for your application.

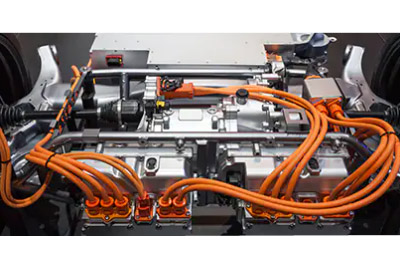

The most cost-effective method of EV battery lightweight is custom die-cutting.

The objective of today's EV OEMs and their suppliers is to produce affordable electric vehicles with sufficient range in a fully charged battery pack to reduce so-called range anxiety (consumers getting antsy at the thought of running out of juice between charging stations). The cost and performance of batteries will continue to decrease as technology advances, but this will only get us so far. In the interim, manufacturers must look for ways to maximize the potential of current technologies. This entails reducing the cost of the vehicles while also making the cars lighter.

Custom die-cut components made of flexible, lightweight high-performance materials can help with that. Making changes to an EV's body, battery pack enclosure, or frame may seem like the best option, but doing so is frequently very expensive and time-consuming. But even small, gradual changes to a vehicle's subsystems can make a big difference. A foam gasket here, a peel-and-stick heat shield made of aluminum and fiberglass there. These small details can add up to significant cost savings for the OEM and its supplier.

Knowledge Centre